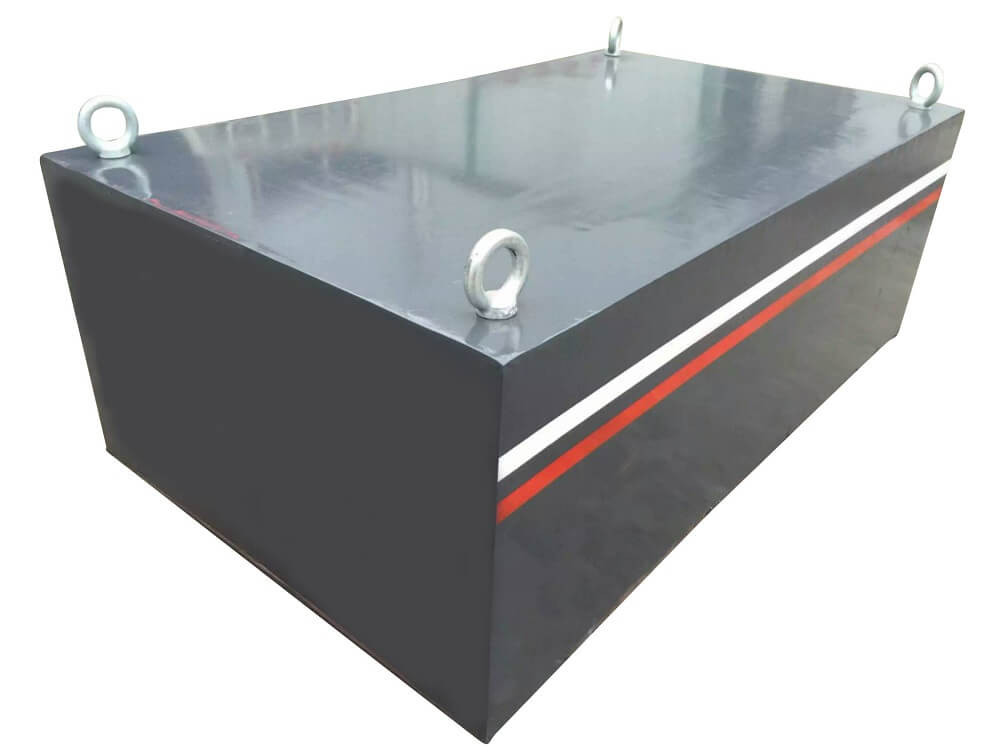

Suspension Electro Magnet

Operating heights are ranging from 150 mm to 600 mm. A stripping mechanism can be added to manually cleaned magnets. There’s no electricity used, and it’s almost maintenance-free.

Applications

- Foundry

- Mining

- Steel

- Coal

Suspension Permanent Magnet

Suspension Magnets are meant to be installed over conveyors when tramp iron contaminants need to be removed for the protection of material processing machinery or to provide a cleaner product. Simply hang the magnet over the conveyor or the head pulley.

Swing the magnet away from the conveyor as the magnet surface begins to fill up, and release the attracted metal with the help of the wiper arm (permanent magnet).

Operating heights are ranging from 50 mm to 400 mm. A stripping mechanism can be added to manually cleaned magnets. There’s no electricity used, and it’s almost maintenance-free.

Suspension Electro Magnet

Electro Suspension Magnets are made out of aluminium or copper coiled coils that are either immersed in transformer oil (to prevent overheating or shorting) or air-cooled for use in harsh or dusty conditions. A control panel is included with all electro suspension magnets.

Permanent Suspension Magnets have the following advantages

- No requirement for a power supply

- No breakdown

- No maintenance