Contact our team – We are here to help you with our expertise Lets start a project together

India Power Melt Pvt. Ltd.

IPM, the health and safety of our employees, customers, suppliers and the communities where we do business is our highest priority.

Induction Melting Furnace

Discover our advanced Induction Melting Furance designed for precise and eddicient.

Continuous Casting Machine

Continuous Casting Machine: Seamless Steel Production for Modern Industries.

Hot Billet Shareing Machine

Hot Billet Shear Machine are designed to provide precise and efficient cutting.

Lifting Electromagnet

India Powermelt provides reliable lifting electromagnets for efficient material.

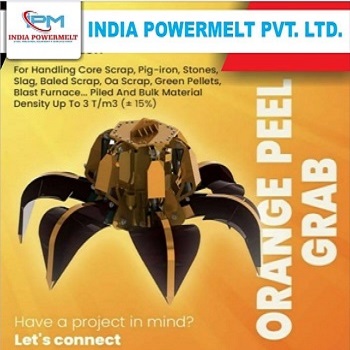

Electro Hydraulic Grab

India Powermelt offers high-quality Electro Hydraulic Grabs for efficient material handling in the metal industry.

Electro Hydraulic Pusher

Looking for high-quality Hydraulic Pusher and cooper Mould Tube solutions.

CNC Rolling Notching & Branding Machine

Precision CNC Notcher & Brander : Superior results guaranteed.

CNC Roll Truning (Heavy Duty) Machine

CNC Roll Truning (Heavy Duty) Lathe Machine In India.

Rolling Mill

Rolling mills are facilities that carry out a series of processes including rolling the billets, blooms, slab and beam blanks – extracted from the reheating furnace – into the prescribed size and correcting any bending.

Scrap Bundle Machine

Scrap Baling Machine also known as scrap baling press or Scrap bundling machine is used to compress waste/scrap into bundles.

Continuous Shear

This construction method is based on a rolled steel beam cut longitudinally, with a special shape, in two T-sections and a concrete top chord is concreted.

Copper Mould Tube

Copper pipes are commonly used in the construction industry for water supply lines and refrigerant lines in HVAC (heating, cooling, and air-conditioning) systems.

Sintering Heater for Furnace Lining

The Sintering heater is to heat the billet to the rolling temperature until it has sufficient plasticity so that it can be rolled to the required cross-section, size or shape by the hot rolling mill.

EOT Crane

EOT cranes are designed for heavy duty material handling in steel plants, warehouses, industrial facilities.

Ladle Slide Gates Mechanism System

Owing to our vast industry experience and expertise, we have been able to offer Ladle Slide Gates Mechanism System.

Pollution System

A major contributor to air pollution and industrial pollution. Steel production is highly polluting because of the industry’s heavy reliance on fossil fuels, especially coal, as its primary energy source.

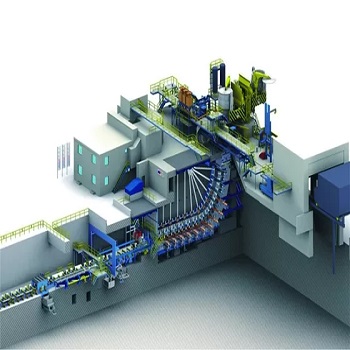

Turnkey Project

A type of project where the contractor provides all necessary resources and personnel to complete the project. Turnkey projects are often used in the construction industry, but can be found in other industries as well.

Steel Plant Project

An industrial plant for the manufacture of steel. It may be an integrated steel works carrying out all steps of steel making from smelting iron ore to rolled product.